Originally published in 2018 and updated in 2021, an in-depth look at the sustainabiliy of responsibly made leather.

White Paper | The Sustainability of Responsibly Made Leather

While it is quite easy to explain what is not sustainable, declaring something to be sustainable is difficult. There is no precise definition of the term sustainable that allows a simple statement of “yes” to the sustainability of a product.

DOWNLOAD PDF

That does not mean that the term is impossible to use, but it should be used thoughtfully as with our partners in the leather industry we fully accept the need for precise language and integrity in this matter. Sustainability has become a “weasel” word thrown carelessly into documents, publicity material and conversations often with only limited interest in the truth. As a consequence we have put together this “white paper” for members, partners, and the industry at large to consider.

The subject of sustainability has expanded in recent years to cover Corporate Social Responsibility (CSR) and more recently Environmental, Social and Governance (ESG). The latter has arisen as the investment and finance communities have started to take an interest in climate change, modern day slave labour, corruption and other issues which have come to the fore as being major risks not only for the future of business but of society itself. It is a very complex matter and we recognise that this will always be evolving and incomplete. We hope it offers useful information in the following areas:

- identifying some clearly stated criteria regarding people, processing and environmental management;

- measuring all criteria and seeking continuous improvement;

- being transparent about all related matters;

- researching for best practice and leading-edge knowledge in order to introduce new procedures and methodologies that will lead to further improvement;

- covering key areas such as waste and staff management where a failure to engage or reach a reasonable standard is an immediate disqualification, regardless of the industry.

It can be seen that we do not see sustainability as a destination but as an ongoing process of learning and improving, albeit the base line standards of responsible tanning discussed later must be achieved.

Based on our 21st century knowledge, we acknowledge that leather making in history would not be categorised as sustainable today.

This is not because either the process or the people involved in leather manufacturing were (or are) inherently bad. Processes and chemicals were used in some periods of history were thought to be safe at the time. As scientific knowledge improved some were identified as problematic or potentially dangerous. There are many similar instances in other industries such as cosmetics and medicines where lead, arsenic. cadmium and other poisonous materials were used extensively in industry before we understood their dangers. Most of the materials used historically in leather making were biobased and today old processes are being re-examined to see if modern versions of these materials might be better than some current chemicals.

“Progress” was seen as important and no one had properly realised the environmental damage it could do as industry grew bigger. In the mid 20th century, the world had a population less than half of that today and the level of damage being done was consequently less, meaning the land and rivers had a better chance to recover.

Leather was the first sheet material humans had available, many thousands of years before textiles and pottery. While the handling of raw hides and skins does create smell, so is best done down wind, until the industrial revolution the tanning industry as carried out was very much a clever biochemical industry and the planet was able to manage and recover from the wastes involved. Properly managed the leather industry produces few wastes as most such material was historically turned into gelatine, glue and other useful products. Society’s problems began as we rushed into global industrialisation based on coal and oil and the sheer volume of the activity started to create issues the planet could not handle. The redefinition of “efficiency” led to some of these non-leather components of hides being viewed as uneconomic to process and disposed of. This is now recognised as having been an error.

Rachel Carson catalysed the change in attitude with the publication of her book Silent Spring in 1962. This book catalogued the longer-term damage being done to the environment by the use of pesticides such as DDT. These had been introduced with good intentions, in large part to try and diminish the damage being done by malaria carrying mosquitoes, but until Rachel Carson, the unintended consequence of such extensive usage had not been recognised.

In December 1970 the Environment Protection Agency was founded in the USA and the Clean Water Act was passed in 1972. Although there had been prior awareness around the world - founding National Parks, protecting birds and trees, and laws regarding the disposal of butchers’ waste - this was the moment that the industrial culture began to change in the leather industry and in many other industries.

The best and most commonly used definition of Sustainability is taken from the Brundtland Commission – Our Common Future, United Nations, 1987. This seminal paper set the environmental agenda and this definition remains the foundation of most contemporary environmental training. Nearly all other definitions of sustainability are derivatives of this. The Rio Earth Summit of 1992 was based upon it.

Sustainability definition (Brundtland):

’Sustainable development is development that meets the needs of the present without compromising the ability of future generations to meet their own needs.’

Brundtland indicated that this definition of sustainability contains alongside it two key concepts:

- The concept of needs. In particular the essential needs of the world’s poor, to which overriding priority should be given

- The idea of limitations imposed by the state of technology and social organization on the environment’s ability to meet present and future needs. (We must advance to develop but in doing so must not deplete the planet of resources future generations might need)

Effectively these say that we must bring people out of poverty as a top priority, and that to do this and to advance society there is a danger of some compromise with the environment, which we must handle thoughtfully without depleting resources.

On the basis of this Brundtland definition, Leather Naturally members now believe that properly manufactured leather will usually meet all the criteria for sustainability. Allied with this we believe that amongst the major chemical and machinery companies involved in the leather industry as well as most top leather manufacturers there has been a major culture change over the last four decades: all now clearly believe that following and achieving the best practice in all aspects of Corporate Social Responsibility and environmental management is the correct thing to do.

It is fully accepted that some mostly smaller, historic, unregulated leather making plants around the world still remain unacceptable. We accept this, recognise that the volume they produce is a very small, albeit significant, part of the global leather business and at Leather Naturally are making effort to press for immediate change. It is required of all responsible producers to be honest and transparent about all that we do and he deficiencies within our industry. In response we do hope that our customers and stakeholders do not choose to condemn our material and industry based on the perception of this tiny minority.

With the bulk leather manufacture looking at the sustainability of leather as a specific more measured item became a serious matter when carbon footprints started to be calculated. Initially a huge charge from livestock was put on leather, while no charge was put on plastics or synthetics from their fossil fuel origins. It has slowly become accepted that this is a flawed analysis and that a more objective, science-based analysis is required.

In so doing the sustainability of leather becomes particularly clear compared to plastics that use up resources from fossil fuels, mostly for a single use before disposal.

Leather starts with a natural material

Starting with a natural material as we move along the leather value chain more and more jobs are created in leather-using industries such as footwear and garment manufacture. Leather and leather using industries have sat in the top five global industries in value and employment until the start of the 20th century, and the huge numbers employed remain significant in times when robots and artificial intelligence are eliminating many jobs. Over the last few decades since 1960, leather using industries have helped pull millions of people out of poverty in Korea, Taiwan, India, China and many other countries. Currently we are seeing this happening today in Africa and other places. Jakov Buljan of UNIDO discussed this multiplier at an industry conference in 2014 indicating 1 sq. ft. of leather (routinely produced) creates 50 jobs in leather using industries. There is no doubt that even a brief look at the numbers employed in a tannery are tiny compared to those required in a footwear or leather goods factory using the output from that leather manufacturer.

Whilst modernisation continues in many areas of leather production there remain large numbers of jobs which require the work of hand and eye from a trained employee; these will not be tasks that can be automated or done by robots, but are essential to add the experiential value that makes leather so suited for consumer use. Leather will therefore continue to offer employment and career paths to pull millions more out of poverty in years to come and enrich the lives of many others who enter at different levels.

It is also important to give prominence to longevity and repair. Based on the work of Walter R. Stahel, who has been influential in developing the field of sustainability by advocating the 'service-life extension of goods’ - reuse, repair, re-manufacture. He co-founded the Product Life Institute in Geneva, Switzerland, a consultancy devoted to developing sustainable strategies and policies, after receiving recognition for his prize-winning paper 'The Product Life Factor' in 1982. His ideas were the foundation of what is now known as the Circular Economy in which industry adopts the reuse and service-life extension of goods as a strategy of waste prevention, regional job creation and resource efficiency in order to decouple wealth from resource consumption.

His argument is that using resources for the longest time possible can cut some nation’s emissions by up to 70% through slowing the need to source new materials to replace others at end of life, increase their workforces by 4% through the use of people repairing and refurbishing items and greatly lessen waste. This fits well with leather since leathers last a long time, and the ability to repair a leather item usually depends on the design of the article in which it is used and any other components. Mostly the non-leather elements like zips and stitching are where failures are first seen. The leather itself usually lasts a long time. We accept that heavily pigments leathers and full grain types react differently but even these more heavily coated leathers long outlast plastics if the coating thickness falls correctly within the definition of leather.

When competitors sell plastics or other combinations falsely under the name of leather problems arise. Items do not last as long as expected and it is discovered that they cannot be repaired and have to go to landfill. A short working life and hundreds of years in landfill is typical for many leather alternates. By comparison many natural leathers have patina – which develops meaning that the leather gains in attraction over time, whereas plastic and many other alternates can quickly become dirty and ugly, and become unserviceable through delamination or other problems. It is important that all items should be properly named, and that consumers not be misled.

In 2011 Pete Lankford, design director for Earthkeepers and Timberland Boot company, was quoted: “Leather wins hands down over anything you can think of.” He continued, “If you can buy a pair of boots that last twice as long as a synthetic alternative, you’ll end up with half the environmental impact in the long run”. Timberland and other major retailers, meanwhile, partnered to create the Leather Working Group in 2005 to introduce a rating system for leather manufacturers based on their efforts to reduce their environmental impact. This organisation is now recognised globally as one of the most effective and respected of its type in the materials sector allowing leather purchasers to see and understand the policies and procedures of the companies where they source their leather. Tanners are categorised as either Gold, Silver or Bronze and the protocols used for this regular third-party assessment are regularly updated.

Leather comes from a natural material and is essentially a protein structure stabilised in a conditioning process so that it will not putrefy and will be fit for purpose. This brings it into the category of a biophilic material which is thought to be increasingly important to help consumers navigate the modern urban world of glass and metal and a life burdened with technical devices. Biophilic design first surfaced as a concept in the 1980s when American biologist Edward O Wilson observed how urbanisation was disconnecting citizens with the natural world. The building industry were first to identify the need for natural materials in the built environment as of ever-increasing importance to health and well-being, and this has now spread to the articles of everyday life.

The Brundtland definition was laid down deliberately as a broad definition to create an umbrella that everyone could come under. The intention was that companies should understand the direction of travel and think hard about their business processes. We believe the leather industry has embraced this and the mainstream industry has corrected the vast majority of the issues, having switched mentality from doing only what the law requires to positively trying to adopt and improve best practice.

Changes in the leather industry were helped by the fact that in the 1970s and beyond an increasing proportion of manufacture of leather products - shoes, gloves, bags and garment moved to less developed countries (creating millions of jobs there) and built new well-equipped factories on green field sites. This put pressure on leather manufacturers in the older economies at the very moment many of them realised that they were in the wrong location to meet the new demand, and anyway did not have space to expand their waste treatment plants economically. The result was that many old plants closed and were replaced with modern factories with full environmental treatment and the best equipment for the safe handling of chemicals. Those leather manufacturers who remained in the west were largely those who rebuilt or updated to work to the highest standards.

Everything we eat, hold or wear is based on chemical engineering. As an old industry that pre-dates the chemistry industry, making leather used a lot of bio-materials and mostly swapped these for modern chemicals at the start of the 20th century. The chemicals used in the leather industry are highly regulated and are safe when handled properly. This is no different from any other use of chemicals, be it in packaging, household goods or even the food industry. We should not use terms that are badly defined or inaccurate such as “heavy metal” or “toxic” in relation to leather manufacturing chemicals. This is an abuse of science and quite unhelpful when trying to objectively assess the position.

Situations should not arise where the workforce is not provided with appropriate work wear or storage and handling facilities for chemicals. Equally we fully accept that no untreated effluent should reach the land or water channels. Serious problems will come quickly if people drink or bathe in such water, or more slowly but inevitably if they seep down into the water table. Water tables worldwide are under serious pressure as urbanisation has accelerated and depleted them. Groundwater care is vital.

Properly handled all the chemicals used in leather manufacturing are safe, and the most difficult to remove from the effluent wise is in fact common salt. It has a big impact on drinking water if it gets into the ground water or a river. Leather manufacturers are working hard to reduce its use and to remove it from raw hides, where it is used for preservation, without dissolving it so that it can be retained as a solid.

Chromium is often mentioned as a leather manufacturing problem because of cancer but the cancerous form is not used in leather manufacturing and can only be created through careless processing. The problem with this chromium in any case is not one of touch, but of ingestion.

No effluent water from any type of industry should be allowed untreated into a watercourse where it will be ingested whether it contains chromium or not.

Hides and skins as a by-product

There are many reasons why farmers keep livestock, but making leather is not one of them. Hides and skins are very much a secondary product or, more precisely a non-determining co-product. The hides and skins offer a useful income but never enough to create a primary reason to keep a herd of cows or sheep. In consequence the consumer desire for leather cannot create a bigger supply, indeed as the human population has grown faster than the supply of leather over the centuries we have seen more use of textiles, paper, glass and other materials in uses that were once exclusively leather.

There is an exception with what we call exotics which include mostly reptiles. They constitute less than 1% of leather made in the world but we accept they are an important part of the luxury goods industry. It is fair to say that there is a mixed set of opinions about using them within the leather industry, but this very small sector does not define in any way the nature of the global livestock industry. Leather Naturally does not involve itself in this sector, nor in the fur trade. Leather Naturally considers the wool-on sheepskin business, shearlings, not to be fur but part of the leather industry.

What we definitely expect is transparency and honesty about the origins of skins, and assurance that everything tanned is CITES approved. We note that some of the bigger luxury goods companies have bought into the supply chain in order to have control not only of the supply but also of the ethics and procedures involved.

There is then a non-exotic intermediate category of such skins as kangaroos which are culled for environmental reasons, where environmentalists mostly consider that it is important that the meat be eaten, and the skins tanned to help cover the costs of the environmental processes involved. Around the world environmental experts nearly always suggest it to be important to use the meat and hides of culled animals, be they deer in Wales or kangaroos in Australia. Again, as with reptiles, the volumes of these categories is a fraction of 1 per cent of the total leather made.

All the cattle, sheep, pig and goat hides and skins that come to the market to be made into leather are by-products. None are bred or slaughtered with the primary purpose of making leather. This thinking has been accepted by the EU and is defined in their category rules for building the carbon footprint of leather and to work out Life Cycle Analysis: "Product Environmental Footprint Category Rules" (PEFC) 2018

Alternate uses for hides

During the 2008 financial crisis as well as the Covid19 pandemic crisis the dramatic upset in the market place suddenly reduced the demand for some hides, and in a few cases abattoirs that were not set up to preserve and store the hides had to throw them away. In consequence it is often noted that leather making is useful to avoid the waste problems that would arise if the leather manufacturing industry closed down.

The proteins in hides and skins are edible and useful in other ways and while it is true that the infrastructure today is only suited to use hides and skins for leather production, we suggest other outlets could arise if leather use was not available. There is quite a big demand for such products as gelatine, sausage skins and the many others uses in cosmetics and medical products. Currently these are met by using only some parts of the hide or using bones and hooves. During 2019 and 2020 there has been increasing evidence that diverting hides into alternate uses in difficult and in some countries both unwanted cattle hides and sheepskins have ended up in landfill, creating a considerable cost for the abattoir to avoid environmental harm. It is thought this has amounted in the USA to 15% or more of all hides.

History has led society to believe that making leather was the best way to utilise this by-product and we believe It still remains the case.

Livestock rearing

The fact that hides and skins arise regardless of the consumption and demand for leather mean that for most scientific measurements what happens with livestock can be said not to be a matter for the leather manufacturer and this is the calculation that comes from the EU PEFC.

Yet leather manufacturers have always been interested in the husbandry and welfare of animals and are increasingly placing this as an important item in their CSR agenda. From the historic “warble fly” in Europe which was eradicated there in the mid 20th century largely at the instigation of leather manufacturers to the current “ekek” in Ethiopian sheepskins tanners need to be involved with the farming community to get improvements. Essentially the better the animal welfare the better the hides. The end of warble fly was recognised as a major benefit to cattle welfare and tests done on Ethiopian sheep show that ekek treatment leads to a much healthier animal, more and better meat as well as a better quality skin.

The main argument against livestock (other than those coming from animal rights and vegan groups) relate to methane, water and energy consumption first raised in the 2006 report “Livestock’s Long Shadow”. Subsequent studies have shown this report to be full of errors, not least from assuming that all cattle are kept in the same maximum emission way. Around the world livestock are kept in a wide variety of ways suited to local climate and conditions. In most of the world the land they graze on is not suited for food crops or forestry and increasingly they are used in a controlled way to maintain or improve biological diversity on grassland and intermediate land.

The complaint regarding methane from cattle is predicated on a historic view that compares methane wrongly on a number of fronts and has become dangerously misunderstood to the extent that society is close to making serious errors in decisions related to farming and diets. Two charts help to illustrate the points which have been well researched and explained by work at UC Davis in California by Professor Frank Mitloehner and at the Oxford Martin School at Oxford University by Dr. John Lynch.

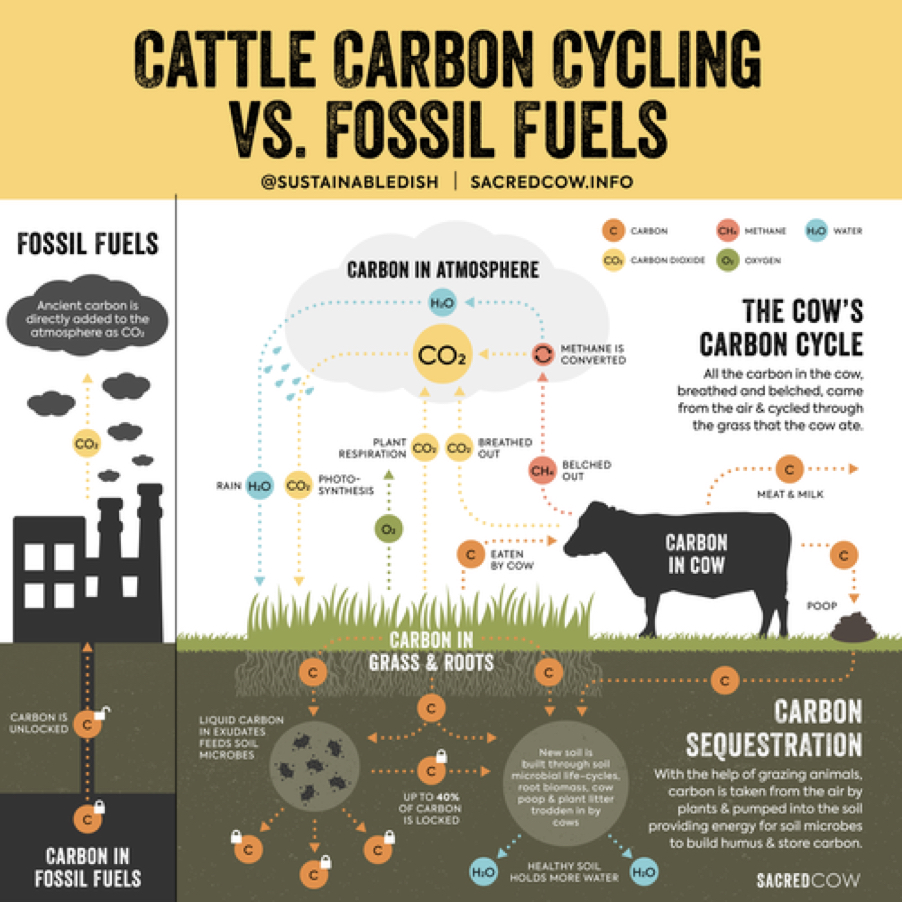

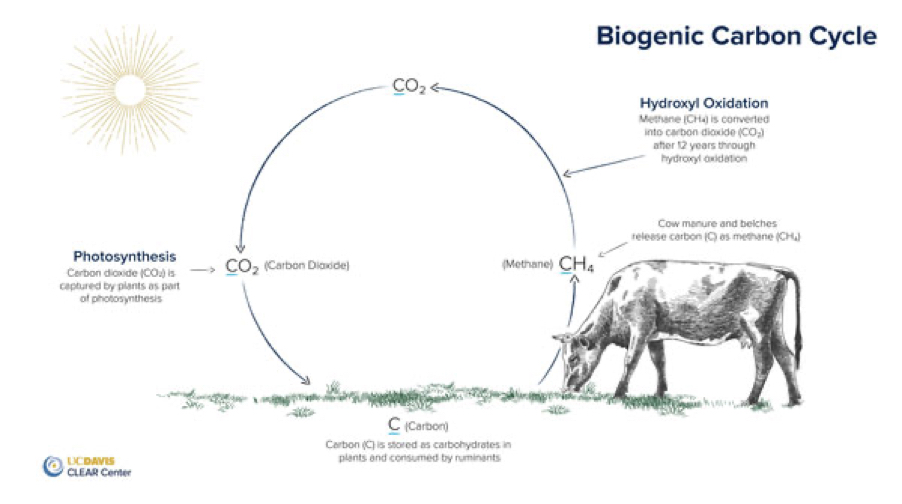

To simplify what is complicated science using mostly their own words biogenic and fossil methane originate from different sources. Biogenic methane starts as atmospheric CO2 before it has been emitted by sources such as livestock whereas fossil methane is geological carbon pulled from deep in the earth, where it has been stored for millions of years.

It is important to recognise that biogenic methane is derived from carbon that’s already in the atmosphere in the form of CO2 and it is part of a short time cycle. While chemically they both are exactly the same, but the two types of methane have different warming behaviours over their life-cycles because of their origins and what happens to them. This is illustrated in the following diagrams.

Unlike biogenic methane, fossil methane is not recycled. Once released from under the earth, it produces new/additional carbon after oxidation and hence, additional warming to the atmosphere. This methane eventually converts to CO2 and because fossil CO2 builds up in the atmosphere at an alarmingly fast rate earth’s natural carbon sinks – the ocean, soils and plants – get overwhelmed. They can only sequester so much carbon.

Carbon sequestration is the process of capturing, securing and storing carbon dioxide (CO2) from the atmosphere. This stabilises the carbon dioxide in solid and dissolved forms so that it does not cause the planet to warm. Fossil CO2 stockpiles in the atmosphere, thus making it what is called a stock gas. Biogenic methane flows through a cycle and is produced and is destroyed at almost equal rates, making it a flow gas.

Regardless of the source, all methane causes warming. But if emissions of biogenic methane equal what’s being destroyed in the atmosphere it does not add more warming to the atmosphere, since there isn’t additional carbon being added.

This means that if the livestock population stays steady there is no additional CO2 being added to the atmosphere although if the global population declines, as has been happening since 2000 there can actually be a cooling effect on the planet. This cooling effect can only happen if the fossil methane and carbon dioxide stays underground where it has been for millions of years.

This biogenic carbon cycle is what makes our plants and trees grow and the long-term grassland that most of our livestock live on move the CO2 down to the roots and deep into the ground where only deep ploughing can remove it. Long term grassland and the huge area of the planet not suited for forest or crops are not ploughed and modern farming has now recognised that direct drilling is environmentally better than traditional deep ploughing.

Long term grassland appropriately grazed by livestock has been proven to be better for biodiversity and for resilience to floods and droughts than arable landscapes and short-term grass. Trees are of course of major importance but many of the current plantings are commercial where the trees will be cut down in a few years, and in other areas climate change makes them vulnerable to loss by fire. In other examples, trees have been put on peat lands and marshland which has a negative impact of biodiversity. The balance is therefore important and long-term grassland and meadows are one of the world’s most damaged sectors over the last fifty years.

Why Leather

Properly made and sourced we believe leather is a truly sustainable material. We are creating a product that is both natural and long lasting - leather is unique in its ability to combine beauty, comfort and practicality.

Given the extensive range of raw materials with different properties, and the many processes developed over time leather making is highly versatile and leather manufacturers can produce leathers with widely varied properties and looks. From a thick hard piece of cattle hide used for a sole leather to a soft thin chamois leather from a sheep which can absorb large amounts of water leather can be adapted in terms of properties, look and feel to be suited for many end-uses. While substitutes are being developed from plastic, cellulose and other biomaterials the complexity of leather in terms of both chemistry and architecture is very hard to copy. This versatility in terms of performance and beauty is the explanation for leather still being accepted as an important and useful material in society after so many thousands of years.

Beauty: leather can look and feel rich and luxurious. It can be tanned and conditioned to create a wide range of finishes and colours, and to achieve a beautiful balance between form and function. And many leather products become more beautiful and interesting with age; in fact, the more you use some leather articles, the more it acquires a unique character all its own.

Comfort: leather is comfortable because it can absorb moisture such as perspiration and it breathes. Its fibrous construction has memory and shapes to your own use over time, be it a jacket, footwear, bag or wallet tucked into a pocket. And a range of textures is achievable, from soft and supple to firm and rugged. For items like gloves leather manufacturers adapt its stretch characteristics to create a perfect tight fit.

Practicality: leather offers protection from wind and cold and can be made resistant to rain and snow. It is durable and can usually be easily cleaned with little more than a damp cloth (check the labels to see about washing or dry cleaning). Quality leather is often made into products that are timeless, fashionable classics that will last a long time.

Conclusion

Given the wide range of raw material and processes leather is a versatile material. It comes in many types and forms. While work for further improvement is needed in every part of our business network from farming through to the design, consumption and disposal of products made of leather we believe we have enough clarity to be able to say that responsibly manufactured leather is sustainable.

Mike Redwood

March 2018 updated January 2021

Increasing beef production could lower greenhouse gas emissions in Brazil if decoupled from deforestation

(5 pages) 28 Apr 2016 In: Nature Climate Change, vol. 6, pp. 493-497

DOI: https://doi.org/10.1038/nclimate2916 Research output: Contribution to Journal › Article (Published)

Hides as a by-product, the US example by Steve Sothmann

https://www.leatherworkinggroup.com/news/latest-news/hide-economics-leather-s-status-as-a-byproduct

GWP100 or GWP* Reporting: https://www.oxfordmartin.ox.ac.uk/publications/demonstrating-gwp-a-means-of-reporting-warming-equivalent-emissions-that-captures-the-contrasting-impacts-of-short-and-long-lived-climate-pollutants/

Oxford, Oxford Martin School, Livestock, Environment and People, (LEAP) programme by Dr John Lynch https://www.futureoffood.ox.ac.uk/article/a-straightforward-way-of-reporting-how-livestock-contribute-to-global-warming

Biogenic and Fossil Methane as defined by the NZ ministry of the Environment. https://www.mfe.govt.nz/climate-change/climate-change-guidance/about-methane-and-other-major-greenhouse-gases

Methane from Cattle and its warming effect: https://clear.ucdavis.edu/explainers/why-methane-cattle-warms-climate-differently-co2-fossil-fuels

Sacred Cow, the case for better meat https://www.sacredcow.info